MIG's two standards, each showing its capabilities "Test Method for Thermal Insulation Temperature Difference of Thermal Insulation Coatings" and "Standard for Antibacterial Functional Facing Materials for Hospitals"

- Categories:News

- Author:

- Origin:

- Time of issue:2020-07-30 14:00

- Views:

(Summary description)

MIG's two standards, each showing its capabilities "Test Method for Thermal Insulation Temperature Difference of Thermal Insulation Coatings" and "Standard for Antibacterial Functional Facing Materials for Hospitals"

(Summary description)

- Categories:News

- Author:

- Origin:

- Time of issue:2020-07-30 14:00

- Views:

"Test Method for Thermal Insulation Temperature Difference of Thermal Insulation Coatings"

On July 23, 2020, the project was initiated by the Industrial Engineering Branch of the Chinese Institute of Electronics, and jointly prepared by China Building Materials Inspection and Certification Group and MiG (Zhejiang) Innovation Technology Co., Ltd. [Insulation Temperature Difference Detection Method for Thermal Insulation Coatings] Submitted for expert consultation The meeting was held in Beijing. Company leaders Wang Qineng, Cheng Xiangming, and Wang Weitao attended the meeting at the MiG branch.

At present, the main thin-layer thermal insulation coatings on the market are divided into reflective thermal insulation coatings, radiation thermal insulation coatings and radiation thermal insulation composite coatings. Among these three types of thermal insulation coatings, only reflective thermal insulation coatings currently have corresponding national and industry standards. In the current standard, the main method to evaluate the performance of reflective thermal insulation coatings is to test the solar reflectance, near-infrared reflectance, and hemispherical emissivity of the coating, which cannot directly reflect the thermal insulation performance of the coating.

There is no corresponding national or industry standard for the new thermal insulation coatings represented by MiG. In addition, the thermal insulation principles of the products are different, the applicability of the standards is unreasonable, and the test results of the new thermal insulation coatings are not ideal. It has brought a series of problems to the testing of third-party organizations, the production of coating companies and the use of construction developers. Therefore, it is imperative to formulate a test standard that takes the thermal insulation temperature difference as the test index and can scientifically, accurately and directly reflect the performance of the thermal insulation coating material.

The standards development team has organized and investigated relevant domestic and foreign standards, regulations and requirements, as well as relevant technical methods and scientific research documents at home and abroad. Directly testing the temperature of the space is used, and the heat source is changed from ‘simulated sunlight’ to ‘hot water heating’, which is consistent with the current heating form of construction projects. Based on the principle of simulating the actual heating of buildings, the design and manufacture of testing equipment are carried out. By comparing the thermal insulation temperature difference index of common materials and thermal insulation coatings, the verification of distinguishing material types is carried out, and the test evidence is analyzed to obtain thermal insulation. There is a significant temperature difference between thermal insulation coatings and common materials.

According to the opinions of various experts, this standard has added detection parameters. The temperature difference between the original tested paint and the common reference paint on the side facing the coating has been increased, and the temperature difference on the side facing the coating has been increased. At present, the instrument and equipment can achieve stable test results. At the meeting, all experts and participating organizations jointly determined that the coating thickness of the coatings of this standard should not exceed 0.4mm. It is reported that the standard will be released soon, so stay tuned.

"Standard for Antibacterial Functional Facing Materials for Hospitals"

On July 28, 2020, the second "Standard for Antibacterial Functional Facing Materials for Hospitals" was initiated by the China Building Decoration Materials Association, the editor-in-chief of the China Building Materials Research Institute, and the participation of MiG (Zhejiang) Innovation Technology Co., Ltd. The working meeting was held in Beijing. Company leaders Wang Qineng and Wang Weitao attended the meeting at the MiG branch.

Hospitals are the main places for patient concentration and medical activities, as well as the places where pathogenic microorganisms gather. Indoor air not only contains a lot of bacteria, but also contains more pathogenic bacteria. These pathogenic bacteria are often attached to droplets and dust and deposit. On various decorative surfaces such as walls and ceilings, it is easy to cause in-hospital cross-infection between patients, and between patients and healthy people. Therefore, the formulation of relevant standards for antibacterial functional facing materials used in hospitals is an inevitable requirement for standardizing and guiding the design and decoration of green hospitals.

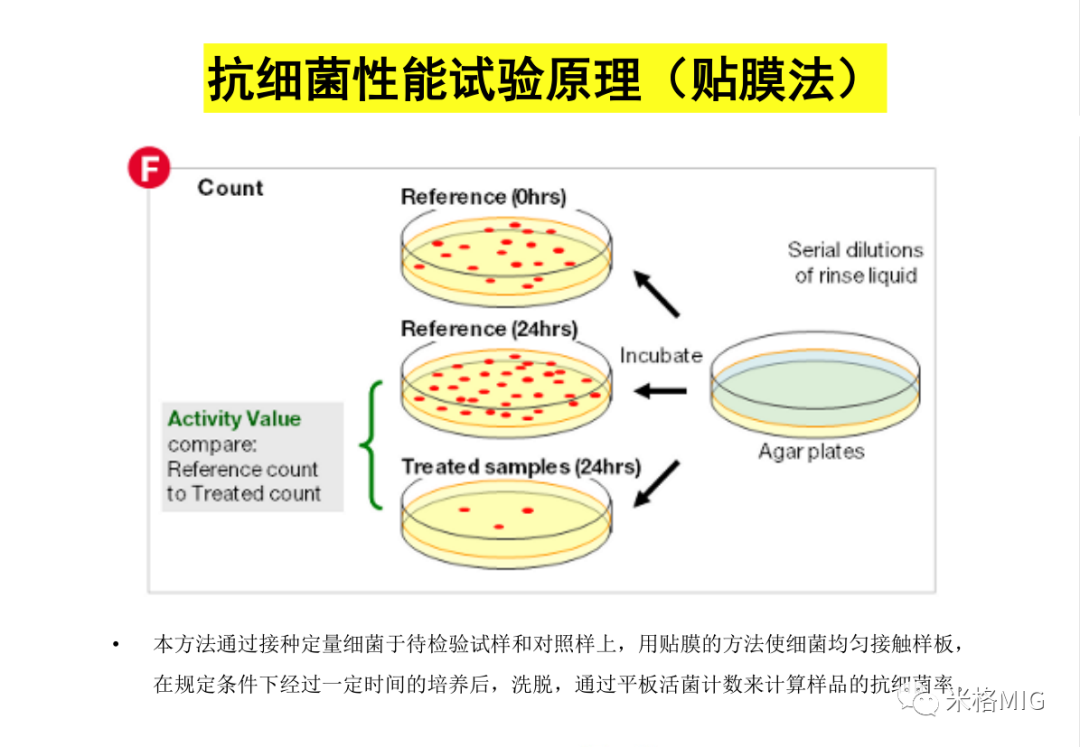

The materials defined in this standard refer to the antibacterial functional building materials with surface decoration effects that can be used in the new construction, reconstruction, expansion and renovation of hospital sites. And in accordance with GB15982-2012 "Hospital Disinfection and Sanitation Standards" and "Disinfection Technical Specifications", the test bacteria, test methods, and antibacterial performance test principles are standardized and explained.

At the meeting, company leaders gave a detailed report on the antibacterial demonstration of MiG material in Europe and the antibacterial performance parameters of MiG material to the experts and leaders at the meeting. Combined with the feature that MiG material itself does not add fungicide, it is recommended that the standard consider antibacterial In the definition of effects, environmental protection and product safety must also be considered. It was affirmed by the experts of the compilation team, and the participants also put forward their own suggestions on the antibacterial material's fireproof performance, energy-saving indicators, anti-mildew and antibacterial.

The meeting also discussed other standards such as "Water-based Anticorrosive Coatings for Buildings". The preparation team also explained the division of labor and progress of this standard, and clearly determined the performance indicators in August, and completed the draft for review in September. Hold a standard review meeting. It is reported that this standard will be jointly issued by professional hospital design institutions such as Zhongyuan International Design Institute and MiG.

The power of the king shows his abilities.

Contact us | Store query | Cooperation | News |

Unified national service hotline : 400-926-7598

TEL: 0579-83190888 FAX: 0579-87350196

ADD: No. 88 Lanfeng East Road, Xialixi Industrial Zone, Yongkang City

2016MIG (Zhejiang) Innovation Technology Co., Ltd. All Rights Reserved Powered by: www.300.cn

scan it

Follow WeChat public account